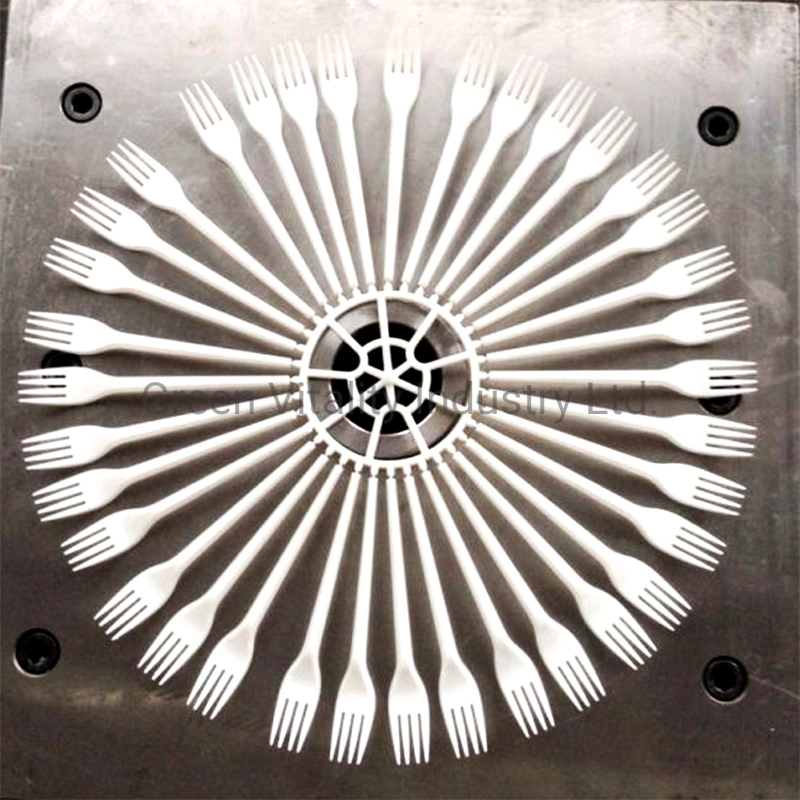

Cutlery Dinner Set Plastic Fork Multi Cavities Injection Moulds

Cutlery Dinner Set Plastic Fork Multi Cavities Injection Moulds 1. Mould Type: Customized plastic injection mould2. Moul

Description

Basic Info.

| Model NO. | Kidyson Mold |

| Runner | Hot Runner & Cold Runner |

| Design Software | Ug, Proe, Auto CAD, Solidworks, etc. |

| Installation | Fixed |

| Certification | ISO, as Per Request |

| Standard | Lkm, Dme, Hasco, Daido, Misum, Customized |

| Customized | Customized |

| After-sales Service | Technical Support, Maintenance |

| Transport Package | Box, Plywood Case |

| Specification | customized |

| Trademark | Green Vitality |

| Origin | China |

| HS Code | 84807100 |

| Production Capacity | 500 Sets of Moulds Per Year |

Product Description

Cutlery Dinner Set Plastic Fork Multi Cavities Injection Moulds1. Mould Type: Customized plastic injection mould2. Mould Steel Material: NAK80, S136, SKD61, P20,1730hh, 2738hh, 718h, H13, etc.3. Mould Dimension (mm): As designed4. Mould Weight (kg): As designed5. Mould Cavity Number: Multi Cavities6. Runner System: Cold Runner / Hot Runner7. Mould Components Standards: DME, LKM, HASCO or equivalent, Customzied9. Surface Treatment: Mirror Polish, Matt, Texture, Customzied10. Mould Life (Shots): 300,000 ~ 1,000,000 shots as per request11. Lead Time: 20~45 days depending on mould complexity.

Plastic Injection Moulded Parts:

A variety of plastic material PC, PA, POM, ABS, ABS+PC, PE, PP, PS, PMMA, TPE,TPU... selected as per specific application.

Plastic Injection Moulds:

Single & Multi Cavity Mould, Hot & Cold Runner Mould, Two-Shot Mould, Insert Mould, Over-moulding Mould, Unscrewing Mould, Gas Assisted Mould, Precision Mould.

One-stop Service:Green Vitality provides a full spectrum service for designing and building moulds, maintaining and running moulds. We can help from design through final production process for product development. * Free Quotation * Moldability Suggestion * Mould Building * Moulded Parts Series Production

Quality Assurance:

The quality control procedure and management system are strictly carried out according to ISO9001:2015 system in Green Vitality.Green Vitality uses professional form and graphics such as BOM of mould, Weekly Report with pictures, Injection Parameter Report, Dimension Report and so on to manage all of projects running process. Quality inspection guidelines are tailored to meet specific customer requirements.

Company Profile:

Green Vitality Industry Co., Ltd has been dedicated to the mold industry since 1993. With the modern business management system and ISO 9001-2015 Quality System guideline, the sophisticated production techniques, the modern manufacturing equipment, and our qualified and dedicated team, we are full of capabilities in offering professional one-stop solution of mould designing, mould making, injection moulding and beyond-value service. We have established strategic partnership with our customers, and continually improve top quality moulds and plastic parts to keep customers' satisfaction and success. Green Vitality is growing up together with our customers.Around 80% of moulds and plastic parts are exported to US, Spain, Germany, Norway, Australia, UK, France, Italy and other countries worldwide.

When you work with Green Vitality, you'll notice that:--- Signed Confidentiality Agreement to protect your proprietary data.--- Factory direct quotation with competitive price.--- In-house production capability for both moulds & plastic moulding parts.--- 30 years experience.--- Dedicated sales team to communicate efficiently.--- Design & Project engineer team offer scientific solution to overall project purpose.--- Support your schedule.

Injection Workshop:

With diversity tonnage injection machines in-house, Green Vitality is able to produce tailor-made plastic moulding parts of small, medium or large volume.Minimum order quantity start from 100 pieces is very beneficial for the business beginners and early stage of new product development. Fully automatic robotic arms are applied in plastic injection moulding process under 24 hours nonstop mass manufacturing, which make production more effective and economic.

Mould Workshop:

Our tooling workshop owns precision mould processing equipment. which enables us to build customized moulds compliant with the international standards such as LKM, DME, HASCO, Daido, Misum etc.We design moulds depending on your annual production requirements, and moulds would be built to fill the capacity of your injection machines

Post Processes:

You could rely on Green Vitality to supply a "complete, turnkey package" by completing all necessary assembly and packaging, resulting in a finished product sent directly to you. ----Product Surface Finish--- Custom LOGO Printed--- Product Assembly--- Custom Labeling & Retailed Packaging

Transportation:

FRQ:1. Are you a trading company or a manufacturer? Green Vitality Industry is a mould manufacturer with around 30 years experiences, we are happy to show pictures or vedio of our workshop, and welcome to visit our factory.2. Which kind of product can you make? Precision plastic injection mould & mass production for moulded plastic parts.3. Do you support OEM? Yes, Green Vitality can produce customized parts by technical drawings or samples, actually above 90% of our products are OEM.4. If no 3D drawing or samples, how should I start the new project? You can tell us your idea (sketch or picture with sizes), we will help to finish the 3D drawing design.5. How about the samples? We will make some samples for you to check as soon as we finish the mould, and then deliver the samples for you to test.6. How about the mould modification? You can tell us your feedback after you test the sample. If there is any dimension different from the drawing, we will modify the mould for free and then make the new samples.7. How about the proprietary rights of the mold? The mould belong to the customer who pay for it. Green Vitality Industry to maintain and keep the mould only for the customer.8. What kind of trade terms can you do? EX-WORKS, FOB, CIF, DDU, DDP 9. What is your terms of payment? For moulds: 40% deposit, mid term 40% upon first shot of sample, final 20% after samples confirmed but before shipment. For parts: 50% deposit, balance 50% before shipment. 10. How about your delivery time? Generally, it takes 40 days (30 days for mould and 10 days for mass production), it depends on how complex of the part design and mould structure.

Green Vitality would always keep our promise to conduct business honestly !Thank you for your Attention !

Our Contact

Send now