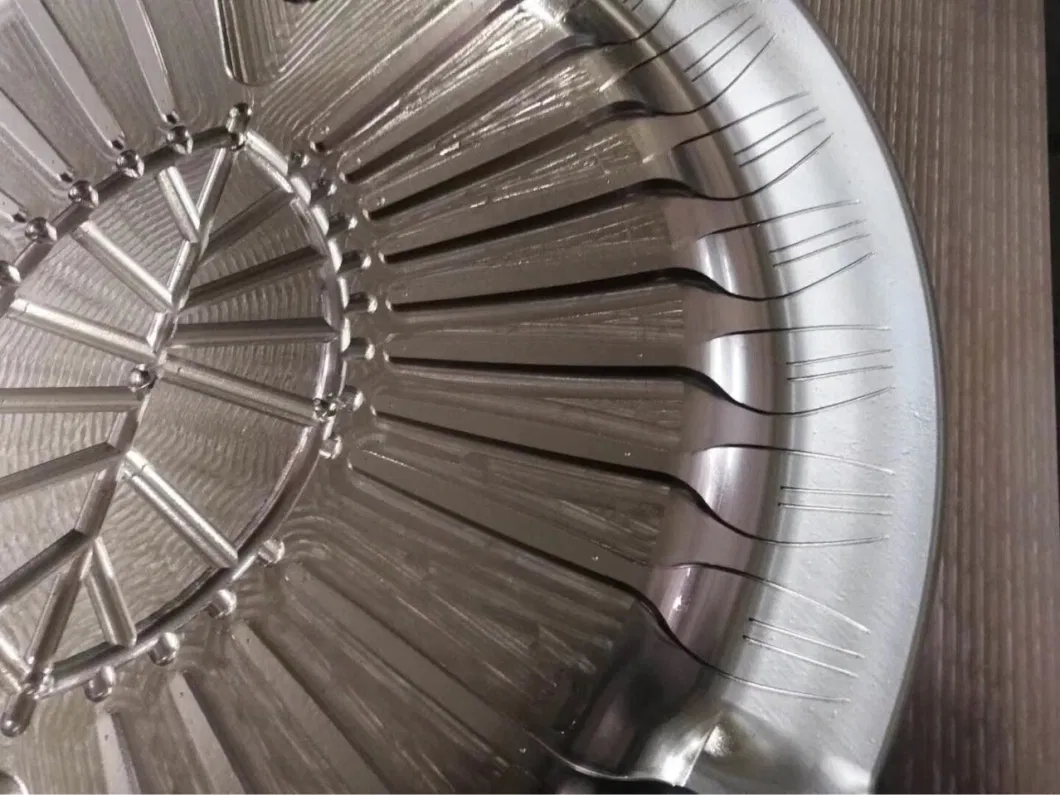

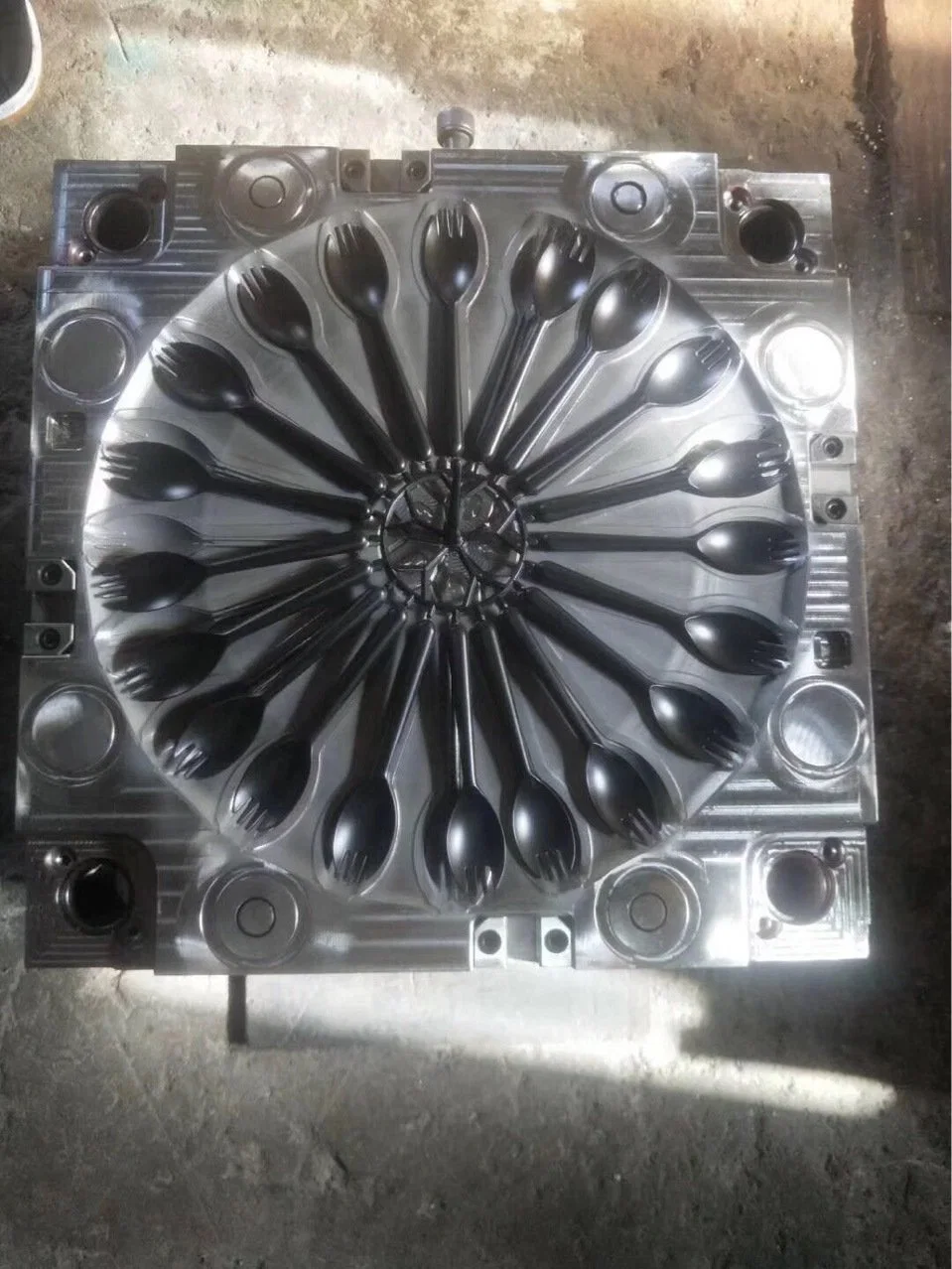

Cutlery Moulds Disposable Knife Fork and Spoon Mold for Restaurant Camping Barbecue Party Flatware

Plastic Injection Molding Description: Cavity Material:1.2738,1.2343, 1.2344, S7, H13, P20HH, GS738H, LKM738H, 718, 8407

Description

Basic Info.

| Model NO. | mould 009 |

| Application | Household Appliances |

| Runner | Hot Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | TS16949, CE, ISO, FDA |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 1 Years |

| Transport Package | Woodbox |

| Specification | 123*73*135mm |

| Trademark | xianghao |

| Origin | China |

| HS Code | 8480410090 |

| Production Capacity | 50sets Per Year |

Product Description

Plastic Injection Molding Description:Cavity Material:1.2738,1.2343, 1.2344, S7, H13, P20HH, GS738H, LKM738H, 718, 8407, S136, Calmax 635 NAK80, SKD-61,NIMAX, 45#, 50#, Aluminum for prototype mold etc.

RunnerCold runner or Hot runner :YUDO/ HUSKY/MOLD-MASTER/SYNVENTIRE/INCO/ MASTIP/ HASCO/ DME

GateSubmarine:gate, tunnel gate, side/edge gate, direct gate, pin point gate, sprue gate, diaphragm gate, fan gate, cashew gate, hook gate, hot tip, hot drop, valve gate etc.

Plastic material for parts: PS, SAN, PA, POM, ABS, PP, PET, PC, PE, HDPE, PA66+GF, PVC, TPE, TPU, TPV etcProcessCNC, high speed carve, EDM ,wiring-cutting, drill, polish etc.

Lead Time:10-30 work days depends on the structure and size of products

Package: Wooden Case Package or according to customer requirement.

Price Term: EX Works, FOB NINGBO, China, CFR, CIF, DDU, DDP.

Product Process:

1. Mold Design Control 2. Mold Steel Hardness Inspection 3. Mold Electrodes Inspection4. Mold Core and Cavity Steel Dimension Inspection 5. Mold Pre-Assembly Inspection 6. Mold Trial Report and Samples Inspection 7. Pre-Shipment Final Inspection 8. Export Product Package Inspection

Prev: Multi Cavities Custom Plastic PP Spoon Mold Disposable Cutlery Injection Mould for Sale

Next: High Quality Custom IMD Iml Moulds Cosmetic Plastic Product Injection Mold Making

Our Contact

Send now